RECYCLING OF JUTE WASTES USING PULPZYME ENZYME

Abstract

In this paper, enzymatic treatment of jute wastes using pulmozyme was studied. The jute wastes from the machine-made carpet-production factories were used as a model. The effects of several parameters such as enzyme concentration, pH and time on the recycling process were evaluated. The optimum enzyme concentration, reaction time and pH for the recycling of jute wastes were 1.5 %, 2 h and 8, respectively. The results showed that the enzymatic process using cellulose was an effective method to hydrolyse cellulosic chains, shorten cellulosic fibers such as jute and decrease its moisture regain (%). The products obtained from the enzymatic process using pulpzyme are suitable raw materials for paper-making processes due to their length range between 0 mm to 4 mm.

Keywords: recycling process, jute wastes, pulpzyme enzyme, mass loss, length reduction, fiber shortening

INTRODUCTION

Waste management is an important issue in various industries. Nowadays, environmental concerns, ecological and economic considerations constitute the driving force for the waste management in the textile industry. In these cases, managing wastes involves modifying the old systems, developing new processes to limit, optimize and process waste materials and finding usage for post-consumer textile wastes.1 Managing wastes in a correct way will lead to saving the energy and cost, reducing the landfill usage and solving the present environmental and ecological problems.2 According to the importance of the recycling processes in developed countries, different physical, chemical or biological methods are used to recycle various wastes from different industries. Cellulosic wastes such as cotton, viscose, lyocell and jute constitute a major part of the textile industries such as the machine-made carpet production. Nowadays, different methods such as chemical and biological ones are used to recycle these wastes. Some of the chemical processes proceed slowly; therefore, catalysts (especially enzymes) are needed to enhance the rate of chemical reactions. In these cases, a small quantity of an enzyme is able to react with a large amount of a substrate in a mild condition.3 Hemmpel4 used cellulase enzyme in different pH conditions to modify woven and knitted cellulose fabric.

The results showed that cellulose enzyme has a significant effect on cellulose fabrics when pH is lower than 5, by hydrolyzing the cellulose bonds. Cellulase enzyme was used for bio-polishing of cotton, viscose and lyocell fabrics by Garret.5 He concluded that cotton, viscose and lyocell fabrics could be modified using cellulase enzyme due to the surface-fiber removal. The effect of an enzymatic treatment on the fine structure of cellulosic fibers and the properties of cellulose dissolved in aqueous 7.6 % NaOH and ionic liquid were analyzed by F. Dadashian6 and P. Rosenberg et al.7 It can be concluded from the SEM photographs that cellulase enzyme has a significant effect on modifying the fine structure of cellulosic fibers. G. Buschle-Diller et al.8 concluded that the cellulases from Trichoderma viride have a significant effect on the pore structure of different types of bead cellulose. A literature review showed that the recycling of jute wastes using pulpzyme was not studied. In this paper, enzymatic recycling of jute wastes using pulpzyme enzyme was studied. The jute wastes from machine-made carpet-production factories were used as a model. The effects of several parameters such as enzyme concentration, pH and time on the recycling of the jute wastes were evaluated with respect to the mass- and length-loss fractions.

EXPERIMENTAL WORK

The jute waste and pulpzyme enzyme were obtained from the Novo Nordisk and Akij (Bangladesh) Companies, respectively. All the other chemicals were of an analytical grade and purchased from Merck (Germany). The main constituents of the jute fiber are represented in Table 1.

Table 1: Contents of jute fibers

|

Content |

Fraction (%) |

|

Ash |

3.04 |

|

Benzene alcohol |

2.72 |

|

Lignin |

21.61 |

|

Acid soluble lignin |

0.95 |

|

Alpha cellulose |

42.91 |

|

Beta cellulose |

20 |

|

Others |

8.77 |

Jute recycling

Experiments were carried out in a batch-mode reactor with the total capacity of 250 ml. The recycling of jute wastes was performed using a 100 mL solution containing a specified amount of jute wastes (5 g) using pulpzyme enzyme. The solution pH was adjusted using a phosphate buffer.8,9 The samples were withdrawn from the sample point at certain time intervals and analyzed for mass and length losses. The mass- and length-loss fractions were checked and controlled by measuring the mass and length of the jute fiber before and after the enzymatic process. In this study an light projection microscope (400 X) and a Philips scanning electron microscope (690 X) were used to measure the fiber length and evaluate the surface morphology of the enzyme-treated and untreated jute wastes, respectively. The effects of the enzyme concentration (0.5–2 %) on the mass- and length-loss fractions of the samples were investigated by treating 5 g of jute wastes at the pH of 8 at 55 °C for 2 h. The effects of the pH (3–9) on the mass- and lengthloss fractions of the samples were investigated by treating 5 g of jute wastes with a 1.5 % enzyme concentration at 55 °C for 2 h. The effect of the time of treatment (0–3 h) on the mass- and length-loss fractions of the samples were investigated by treating 5 g of jute wastes with a 0.5 % enzyme concentration at the pH of 8 at 55 °C. The mass-loss fractions of the samples were measured by weighting jute wastes before and after the enzymatic treatments. The mass-loss fraction was defined as follows:

Mass-loss fraction /% = (A2 – A1)/A1 × 100 (1)

where A1 and A2 stand for the dry mass and conditioned mass of the samples before and after the enzymatic treatment, respectively.

The moisture regain of the samples was measured with the gravimetric method. The moisture regain was defined as follows:

Moisture regain /% = (W2 – W1)/W1 × 100 (2)

Where W1 and W2 stand for the dry mass and conditioned mass of the samples, respectively. The FTIR spectra were obtained using a Nicolet Magna IR spectrophotometer equipped with a microscope.

3 RESULTS AND DISCUSSION

3.1Enzyme concentration

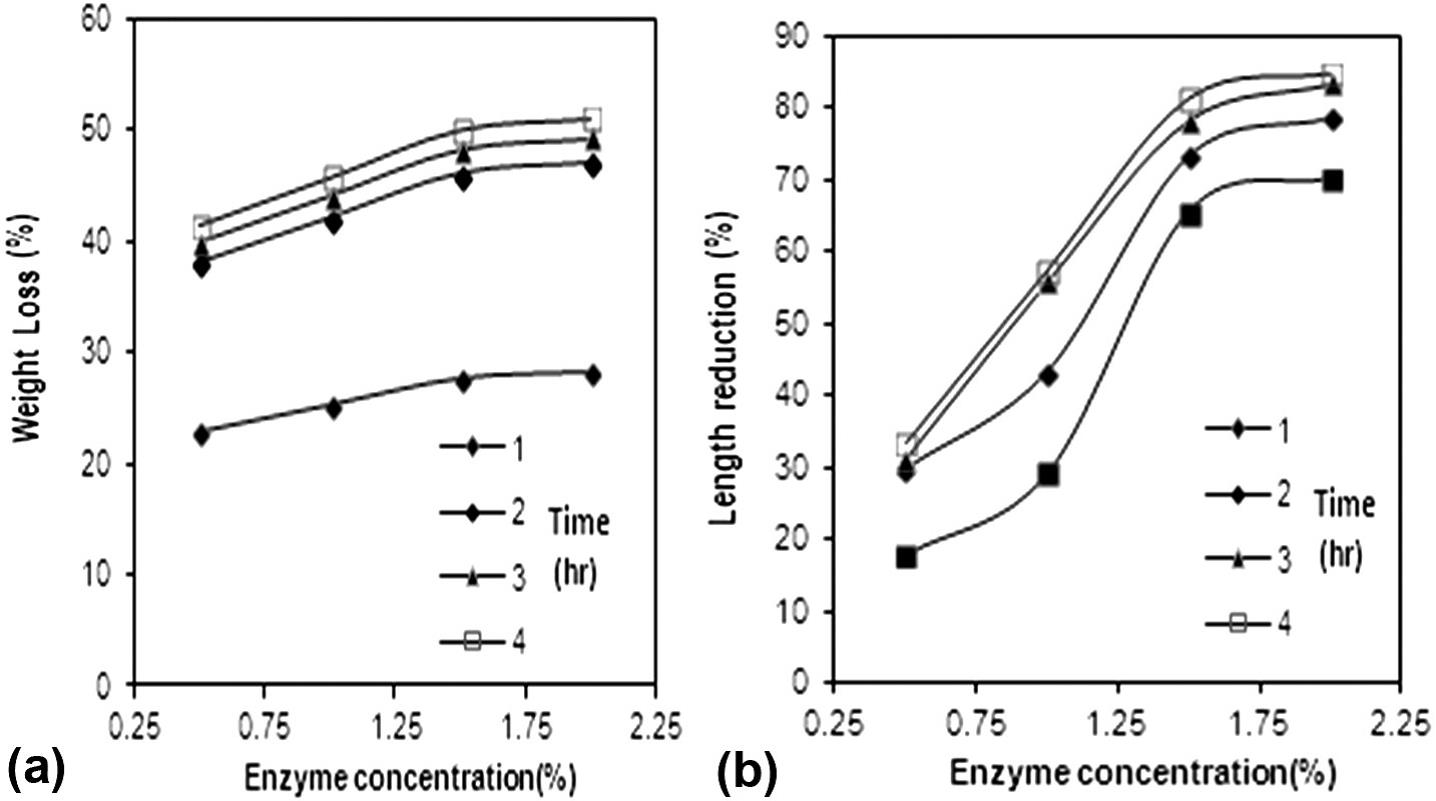

The mass-loss and length-reduction fractions of jute samples for different enzyme concentrations are shown in Figure 1. According to the data from Figure 1, with the increasing enzyme concentration, the mass-loss and length-reduction fractions increased gradually because of the existing excess enzyme molecules relative to the fixed amount of jute. With the 1.5 % enzyme concentration, the optimum mass-loss (almost 46 %) and lengthreduction (almost 73.45 %) fractions were obtained; therefore, the optimum enzyme concentration for the recycling of jute was 1.5 %.

Figure 1: Effect of enzyme concentration on: a) mass-loss fraction, b) length-reduction fraction of the samples

3.2pH

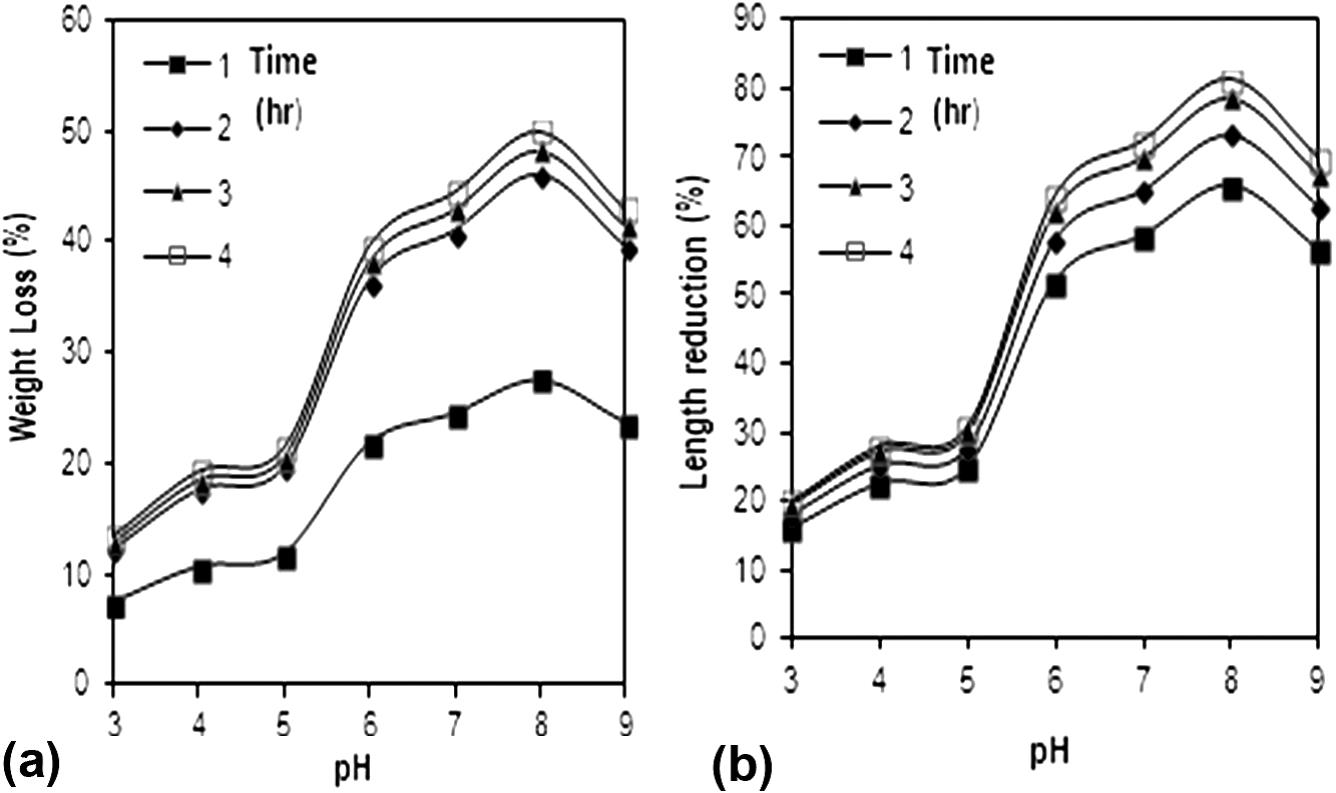

The mass-loss and length-reduction fractions of jute samples at different pH values are shown in Figure 2.The results show that the pH significantly influenced the pulpzyme action during jute recycling. The mass-loss and length-reduction fractions were found to improve with an increase in the aqueous-phase pH up to the value of 8 and, thereafter, an increase in the aqueous-phase pH from 8.0 to 9.0 caused the efficacy of the enzymatic recycling process to decrease. The aqueous-phase pH of 8.0 had a significant effect on the rate of the mass-loss and length-reduction fractions compared to the other pH conditions.

Thus, the aqueous-phase pH plays a significant role in enzymatic reactions. Moreover, the pH-activity relationship of any given enzyme depends on the acid-base behavior of the enzyme and the substrate (the jute waste) as well as on many other factors that are usually difficult to analyze quantitatively.

2: Effect of pH on: a) mass-loss fraction, b) length-reduction fraction of the samples

3.3Time of treatment

The mass-loss and length-reduction fractions of the jute samples at different times are given in Table 2. The results show that the time of treatment significantly influenced the pulpzyme action during jute recycling. The mass-loss and length-reduction fractions were found to improve with an increase in the time up to 2 h and, thereafter, an increase in the time of the enzymatic treatment from 2 h to 4 h was without any significant changes. After the 2 h enzyme reaction, the optimum mass-loss (almost 46 %) and length-reduction fractions (almost 73.45 %) of a jute sample were obtained; therefore, the optimum time for the enzymatic treatment was 2 h.

Table 2: Effect of the time of treatment on mass-loss fraction and length-reduction fractions of the samples for the optimum enzyme concentration and pH

| ( Time hr) | 1 | 2 | 3 | 4 |

| Mass loss (%) | 27.6 | 46 | 48.3 | 50 |

| Length reduction (%) | 65.76 | 73.45 | 78.5 | 81.3 |

3.4Effect of the enzymatic process on the moisture regain

The moisture regains of the samples before and after the enzymatic treatment were measured according to equation (2). According to the data from Table 3, the enzyme-treated jute has a lower (22.37 %) moisture regain than the untreated jute in the optimum condition. The results show that the enzymatic treatment of jute has a specific effect on increasing the crystallinity.

| Sample | (Conditioned massg) | ||

3.5Microscopic structure

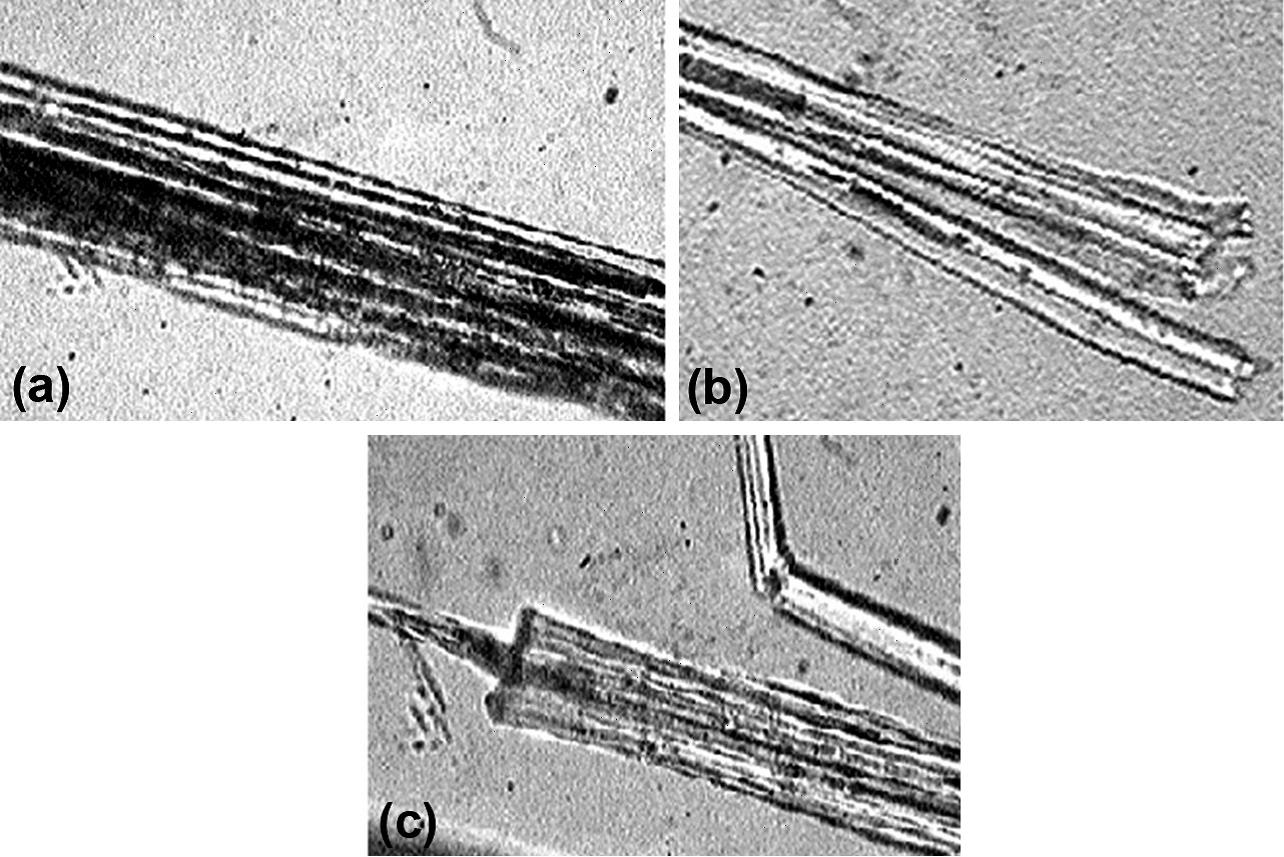

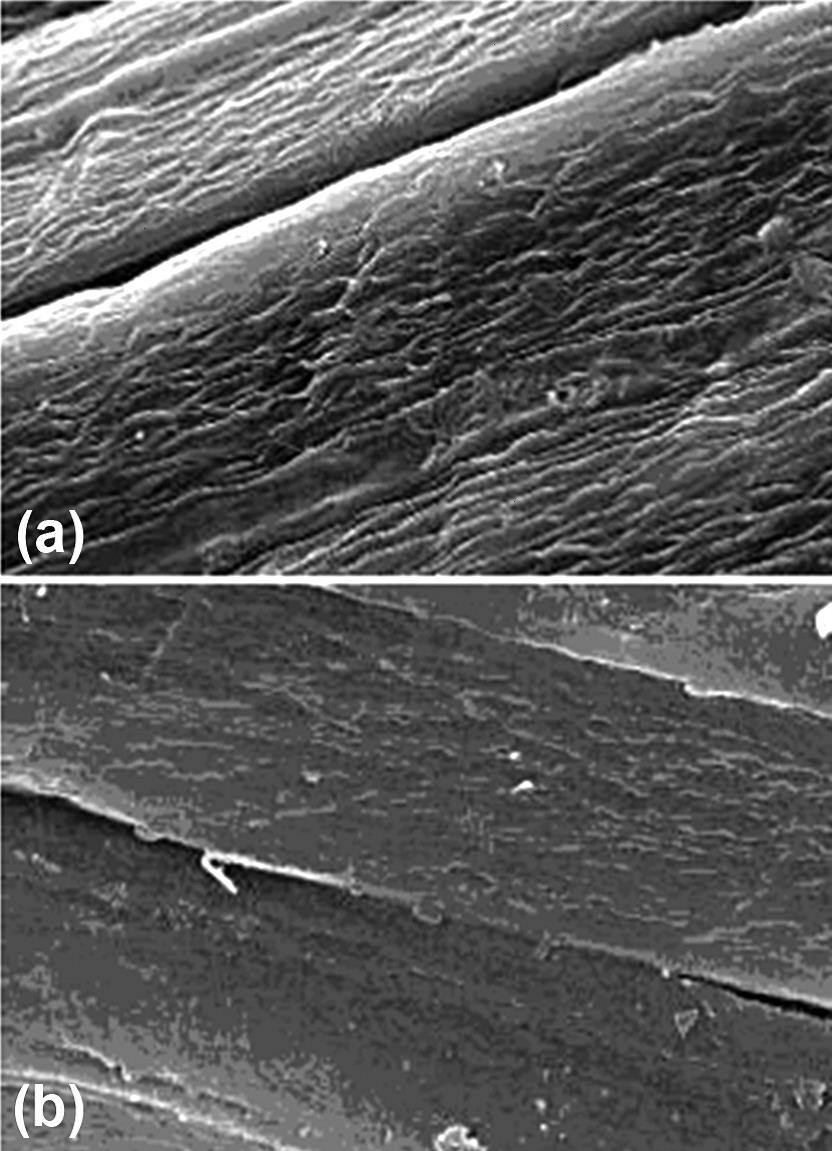

The effect of pulpzyme enzyme on the macrostructures of the samples was studied using SEM and light

microscopic photographs. The light microscopic and scanning electron microscopic (SEM) photographs of the samples before and after the enzymatic processes are shown in Figures 3 and 4. The results show that pulpzyme enzyme has a significant effect on the destruction of the

molecular structure of jute in the longitudinal direction due to the hydrolyzing reaction. This phenomenon has a significant effect on the shortening of the jute samples.

Figure 3: Light micrographs of: a) untreated jute-fibre wastes, b)jute-fibre wastes treated with enzyme in optimum concentration

Figure 4: SEM photographs of: a) fiber wastes enzyme treated with the optimum enzyme concentration and b) untreated jute-fiber wastes

4CONCLUSIONS

In this study, enzymatic treatments were used to modify jute wastes. The effect of several parameters such as enzyme concentration, pH and time on the recycling of jute wastes was evaluated.

The results showed that the enzymatic treatment has a significant effect on the mass loss and shortening of the jute samples by hydrolyzing cellulosic chains.Moreover, the enzymatic treatment leads to a decrease in the moisture regain of the samples due to the increasing crystallinity. It can be concluded from the SEM and light microscopic photographs that pulpzyme enzyme has a significant effect on the destruction of the molecular structure of jute in the longitudinal direction due to the hydrolyzing reaction. Finally, it leads to the shortening of the jute samples. According to the obtained data, the optimum enzyme concentration, reaction time and pH for recycling jute wastes were 1.5 %, 2 h and 8, respectively. The obtained samples are suitable for a usage in the paper-making industries due to their longitudinal distribution.

5REFERENCES

1 M. J. Cornell, Getting to zero Wastes, [cited fall 2007], Available from World Wide Web: http://www.toenall.org

2 L. Wang, Y. Z. Zhang, H. Yang, Carbohydrate Research, 339 (2004),819–824

3 Enzyme kinetics, Thomas Jefferson University, Maintained by AISR Education Services (EdServices@jeffline.tju.edu)

4W. H. Hemmpel, International Textile Bulletin Dyeing/ Printing/Finishing, 37 (1992) 3, 1–5

5 A. S. Garret, D. M. Cedroni, In AATCC Book of Paper, AATCC International Conference & Exhibition, Atlanta, 1992

6 F. Dadashian, Changes in the Fine Structure of Lyocell Fibers during Enzymatic Degradation, Proceedings of the World Textile Conference,

2ndAutex Conference, Bruges, Belgium, 2002, 464–473

7 P. Rosenberg, T. Budtova, M. Rom, P. Fardim, Effect of Enzymatic

Treatment on Solubility of Cellulose in 7.6 % NaOH-Water and Ionic

Liquid, ACS Symposium Series, Chapter 12, 2010, 213–226

8 G. Buschle-Diller, C. Fanter, F. Loth, Cellulose, 2 (1996) 3, 179–203

9 T. C. Ranjan, Handbook of Jute, vol. 3, Oxford and IBH, New Delhi

1973

10 K. P. Katuri, S. V. Mohen, S. Sridhar, B. R. Pati, P. N. Sarma, Water

Resource, 43 (2009), 3647–365

11 K. M. Shojaei, F. Dadashian, M. Montazer, Applied Biochemistry

and Biotechnology, 166 (2011) 3, 744–52